Background

Click here to use the Energy Curves tool

Welcome to the CEEC Energy Curve Program, a tool which allows comminution circuit operators to benchmark the energy efficiency of their operations and to contribute anonymously to the database on which the tool is based.

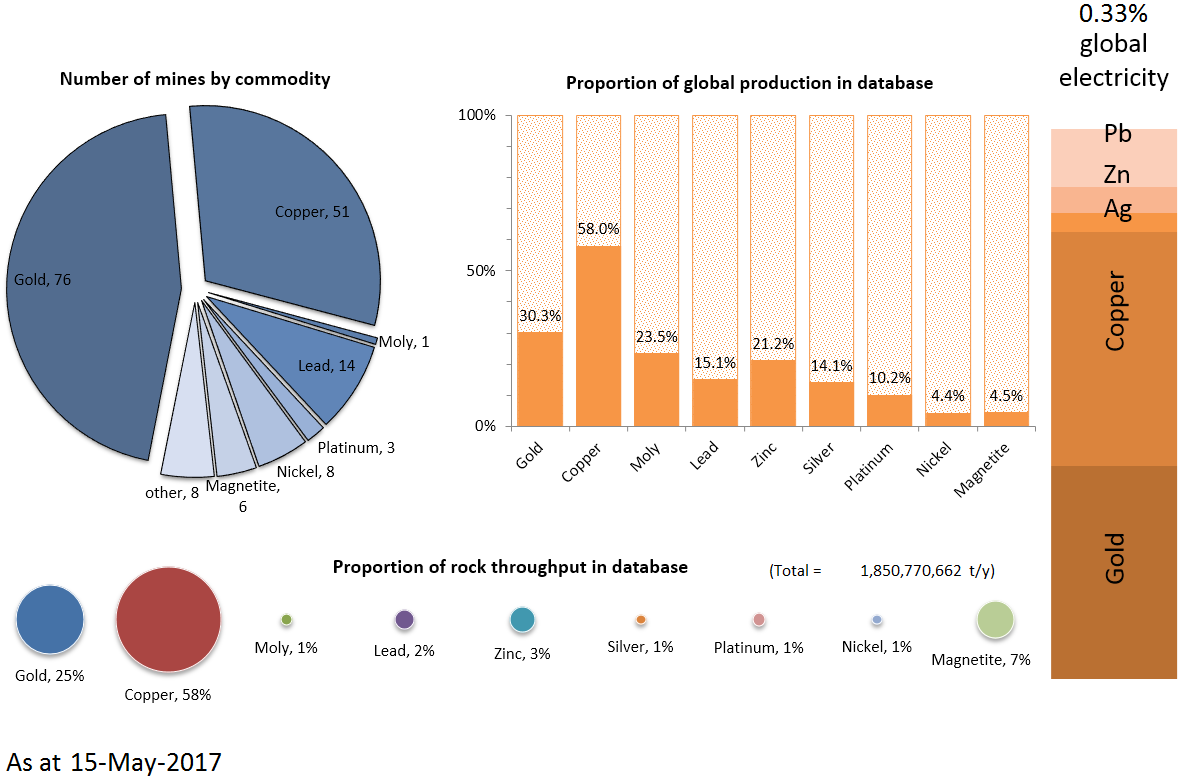

The tool uses the benchmarking ideas presented in a survey of the comminution energy requirements of gold and copper producing mines (Ballantyne and Powell, 2014). This work provides reliable data which can be used to compare comminution energy consumption at different mine sites. The total gold and copper production of the mines included in the original study equated to 15 and 24 per cent respectively of global production and all of Australian production.

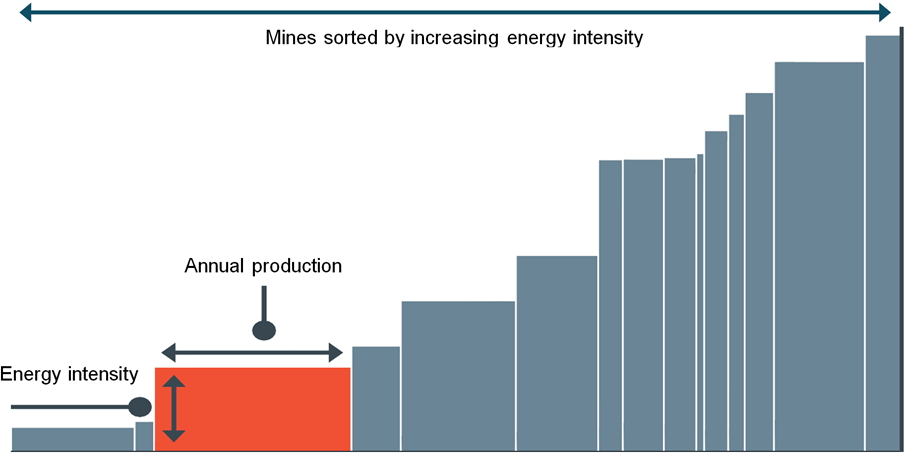

The comminution energy intensity of the mine is presented in a graphical form similar to a cost curve. Each mine is displayed as a separate bar in a bar chart, the width of which represents the annual production. The comminution energy intensity is represented by the height of the bar. This simple technique allows individual mines to be ranked with respect to energy consumption, and clearly displays the potential energy and cost benefits of moving down the graph into more efficient operating regimes. The anonymity of the comprehensive, mine-specific data is maintained and the variability is visualised by constructing an ‘energy curve’. Since these types of curves are well known in the mining industry, this format is easily recognised and can be used to motivate behaviours that will move the mine down the curve. This approach also allows flexibility in the way comminution energy intensity is displayed (e.g. energy per rock milled or metal produced) thus providing a fairer comparison between sites.

The applications of energy curves are many and varied. They can be used to map the position of the mine as production progresses with year-on-year analysis. Operational efficiency improvements can be mapped on the curves to visually assess the magnitude of energy reductions achieved through various strategies. The efficiency with which the various comminution devices achieve size reduction can be mapped down a circuit to identify opportunities for improvement and the magnitude of achievable gains.

Get involved!

To participate in this program, simply complete the survey linked below. All data collected for this program is secured within a two-factor login system, and all communications containing data is sent using SSL encryption. The raw data and the processed information is stored on a secure server, protected and managed by the University of Queensland.

Each operator will receive a secure email from CEEC’s energy curve program manager with their unique results clearly displayed on the energy curves. Each operator will only be privy to the position of his/her operations relative to the other mines in the database.

CEEC provides this analytical service to support the establishment of best practice in mineral processing. There will be no charge for data analysis at this time.

The benchmark database is continuously updated and enlarged as new data become available.

Click here to complete the survey.

Answer as many questions as possible.

Energy Curve profiles

Diagnostic Interpretation

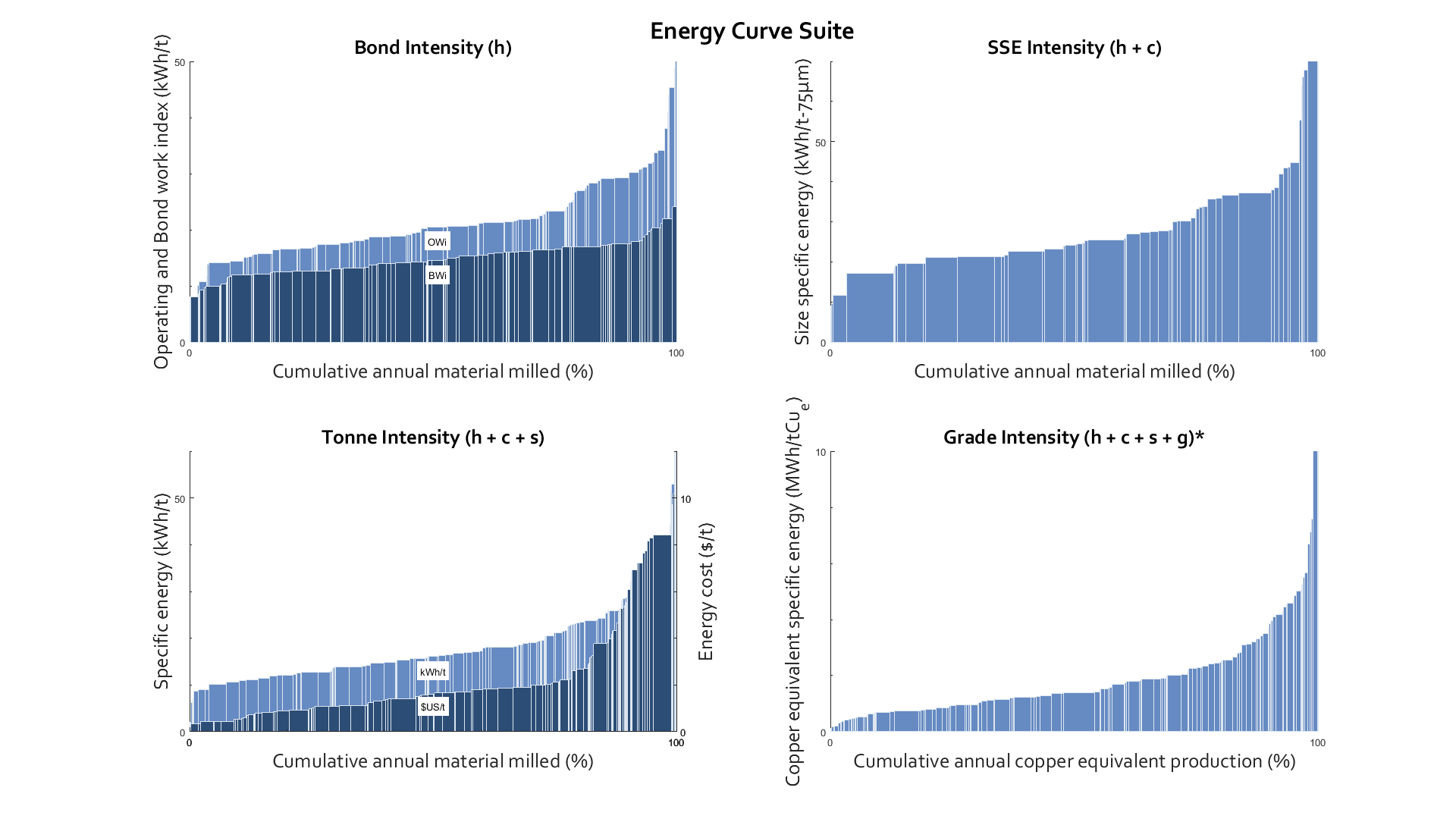

A suite of four energy curves have been configured to rank the relative energy intensity of a mine of interest with respect to the effect of ore hardness, circuit efficiency, grind size and feed grade. The first energy curve shows the impact of hardness as assessed using the Bond Work Index comparative methodology. Both the Bond Work Index (BWi) and the Operating Work Index (OWi) are presented as separate overlayed curves. The BWi is an industry standard laboratory measurement related to the specific energy requirement of a rock for a given P80 reduction. The OWi relates to how much energy is actually used on the plant to achieve the same P80 reduction. Presenting both these parameters together enables the mine to be benchmarked on both the laboratory competence measurement and the achieved energy consumption. Thus, if a mine was found to have an ore that is at the 70th percentile of BWi, but the 80% percentile of OWi (higher on the curve), this would indicate that this mine was underperforming in relation to the ore hardness.

The Size Specific Energy (SSE) intensity is a measure of how much energy is used in generating new sub 75 micron material. The SSE method has been used as an alternative to P80 reduction because it more accurately reflects that the majority of the energy is consumed in the generation of new surface area in the fines fraction (Ballantyne et al., 2015). The use of 75 µm is acknowledged to have no particular value in itself, for coarser of finer circuit products, another marker size would be equally appropriate. Both rock hardness (h) and circuit efficiency (c) contribute to determine the position of an operation on the SSE intensity curve. Thus, if an operation appears in the bottom third of the Bond intensity curve, but near the top of the SSE intensity curve, it would indicate that at least one area of the circuit is underperforming.

The data to derive the tonne intensity curve is the most readily obtained and is most easily understood by the non-technologist. The particle size of the circuit product (s) also affects the position of a mine on the tonne intensity curve. Therefore, the mineralogy of the ore contributes to the tonne intensity because it largely determines the required grind size. A fine-grained ore typically requires energy intensive fine grinding, pushing it up the tonne intensity curve.

The primary output of a mine is the production of metal which is captured by the grade intensity curve. The comminution energy required per unit of metal product is displayed in this curve. Poly-metallic ores are normalised by converting the respective metal values of other constituents to a copper-equivalent production. This is essentially the copper production that would be required to produce the same level of revenue as that from the other metals. The metal prices that were used in this analysis were obtained from annual reports in 2013 and represent the actual revenue realised by the mining companies.This curve displays both the metal prices used and the grade intensity curve coloured by commodity. This shows that using copper equivalent production is useful in comparing gold and copper mines (there is an equal distribution along the curve), but has the potential to under-estimate the contribution of comminution energy in other commodities (grouped at the bottom of the curve). The position of a mine on the grade intensity curve is largely determined by the metal grade of the mined material. Thus, a mine in the upper quartile of the grade intensity curve would likely benefit from investigating pre-concentration strategies such as grade engineering.

These results are updated monthly.

Global production is assessed using data from the US Geological Survey

Reference papers

• Ballantyne, G.R., Lessing, E., Meer, F.V.D., Stocco, R., Hilden, M., 2016. Rigorous characterisation of ball milling requirements from HPGR products, in: International, M.E. (Ed.), Comminution, Cape Town, South Africa.

• Ballantyne, G.R., Powell, M.S., 2016. Using the comminution energy curves to assess equipment performance, in: International, M.E. (Ed.), Comminution, Cape Town, South Africa.

• Ballantyne, G.R., Powell, M.S., Clarke, N., 2016. Energy curve case study (AngloGold Ashanti), in: (SME), S.o.M.E. (Ed.), SME Annual Conference and Expo (ACE), Phoenix, Arizona.

• Ballantyne, G.R., Powell, M.S., Radziszewski, P., 2016. Extension of the comminution energy curves and application to stirred milling performance, Canadian Mineral Processors (CMP), Ottawa, Canada.

• Ballantyne, G.R., Mainza, A., Powell, M.S., 2015. Using comminution energy intensity curves to assess efficiency of gold processing circuits, World Gold 2015, Johannesburg, South Africa.

FAQ’s

What does it cost to participate in this survey?

CEEC is providing this analytical service to support the establishment of best practice in mineral processing. There will be no charge for data analysis at this time.

What specific data will I receive after completing the survey?

Confidential reports will include the position of their operation in relation to other mines, in regards to bond and operating work index (kWh/t), size specific energy (kWh/t-75µm), tonne specific energy (kWh/t) and metal specific (kWh/tCu).

How do I source further information or a more detailed analysis?

More in-depth analysis or guidance on methods to reduce energy consumption should be sought from qualified consultants.

Who is funding this survey?

This project is funded by CEEC International Ltd. CEEC is a NFP global industry body who believe mining is critical to global development, and view best practice as the key to undertaking process improvements and adopting innovative solutions.

Can others see my data?

Data displayed on the CEEC web site will not identify any individual operator, unless CEEC is directed to do so by the operator themselves. Operators will receive secure direct email from the program manager with site specific reports.

How secure is this process?

All data collected for this program is secured within a two-factor login system, and all communications containing data is sent using SSL encryption. The raw data and the processed information is stored on a secure server, protected and managed by the University of Queensland.

Where will my data be displayed?

All processed data will be displayed on the energy curves, without individual site identification. The energy curves will be displayed on CEEC’s web site, and updated regularly.

How will I know which is my data?

Each operator will receive a secure email from our program manager with their unique results clearly displayed on the energy curves. You will only know the position of your own operations relative to the other mines in the database.

Can my operation’s position move along the curve?

Yes, if your operation becomes more energy efficient, your position relative to other sites will move on the energy curve. Note, your position on the curve will move as additional data sets are added to the study. CEEC encourages each operator to use the results of this program to identify opportunities to improve processing efficiency or adopt alternative flow sheet strategies.

Will the combined data be displayed publically?

Yes, but without any individual identification of sites.

Can I use this program to model alternative flow sheet strategies?

Yes, you can use this program to analyse your current operational efficiency, as well as model alternative processing parameters.

How can I be assured that the data is valid and not compromised?

The database currently contains over 100 mines contributing to approximately 20% of gold, lead, zinc and silver global production and 40% of copper. Data has been collected from over 10 different sources and scrutinised to ensure reliability. This level of scrutiny will continue to be applied to data collected from the CEEC website and you may be asked to verify the results that are presented.

Small number of producers

There is only a limited number of operators processing my specific ore /commodity. Confidentiality is crucial to ensure commercially sensitive insight. How will CEEC ensure the results of the analysis of this commodity will remain confidential when compared against other producers in this small industry sector?

The CEEC energy curve does not disclose any individual operation’s details in the public domain. Operators receive a unique confidential report illustrating only their specific positon on the energy curves relative to unidentified others. In addition, results are presented as a percentage of a cumulative total, now in excess of 1.7b tonnes of ore. If a commodity-specific set of curves was produced with platinum, it would be bundled together with gold and potentially silver to give an outcome for precious metals.

Questions?

If you have questions relating to this program please email

Our project partners: